Reliable Limiting of Current Surges by AMWEI NTC and PTC Thermistors

A wide range of AMWEI NTC and PTC thermistor is available to protect the inputs of power supplies from excessive inrush and surge currents. These components are characterized by their high reliability and the fact that they require only minimal additional design-in effort.

High-rated capacitors are used to smooth and stabilize the DC voltage in power supplies after rectification. If they discharge at start-up, they produce a short circuit affecting the rectifier and power line. The resulting extremely high currents can destroy the rectifier or trigger the power fuse. Extremely high inrush currents can also occur with inductive loads such as larger transformers or motors.

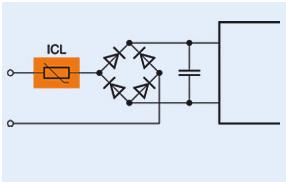

Power Input with AMWEI NTC thermistor as Inrush Current Limiter (ICL)

AMWEI NTC or PTC thermistor offer cost-effective and highly reliable solutions to such problems. NTC thermistors are used as inrush current limiters (ICL) especially for power supplies. Figure 1 shows a simplified circuit diagram of a power input with an ICL.

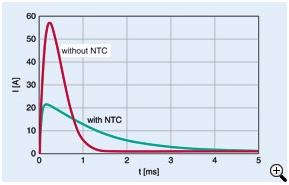

AMWEI Inrush Current Limiters ICL NTC thermistor limits the current at start-up and prevents triggering of the fuse or destruction of the rectifier. NTC-based ceramic Inrush Current Limiters ICLs possess the typical characteristic of an NTC thermistor, i.e. a temperature- dependent resistor. As the temperature rises, their resistance drops. They exhibit a relatively high resistance (1 to 120 ohm, depending on the type) at start-up at 25C, allowing only a low current to flow through the load. This current flow then gradually heats them up so that the current increases further until it reaches its rated value as defined by the load. This behavior consequently assures gentle and safe start-up of the load (Figure 2). As a rule, the Inrush Current Limiters ICL heats up by 10 to 30 K in this phase with respect to the ambient temperature.

Current flows as a function of time comparison with and without NTC thermistors

Inrush current is significantly limited by using an AMWEI Inrush Current Limiter ICL. AMWEI Inrush Current Limiters ICLs feature an extremely low resistance in their conducting state. Their power loss is correspondingly low, at least for equipment of the lower and middle power classes, and their effect on the overall efficiency of the equipment is negligible. For larger power supplies, the ICL may be bridged with a relay after the rated current of the equipment has been reached.

Selection Criteria for NTC thermistors Inrush Current Limiters ICLs

The following data is critical for selecting the correct Inrush Current Limiters ICL:

- The load capacitance which determines the minimum rating of the Inrush Current Limiters ICL.

- The maximum continuous current and the maximum ambient temperature (until the Inrush Current Limiters ICL is bridged after the start-up phase).

- The required reduction of the inrush current at 25C.

- When rating the component, it is crucial that the maximum continuous current never exceeds the maximum permissible current of the ICL (Imax).

AMWEI PTC Thermistors Protect Against Short Circuits

Apart from inrush currents, another danger is represented by excessive continuous currents or short circuits inside equipment. As a rule, the risks come from defective link-circuit capacitors or power semiconductors. These danger sources are eliminated by AMWEI PTC thermistors connected in series.

Unlike NTC ICLs, they have a positive temperature characteristic, i.e. they have low resistance at ambient temperature. Excessive currents then gradually heat up the PTC thermistor inrush current limiter ICLs–which go over to a highly resistive state and thus limit the current.

These ceramic components are practically self-resetting fuses: as soon as the current surge subsides, they cool off and return to their low-resistance conductive state.