PTC Thermistor Limit Temperature Sensors Protect Power Supplies Against Overheating and Thermal Damage

PTC Thermistors Prevent Thermal Destruction

PTC thermistor limit temperature sensors offer perfect protection against overheating and thermal damage.

Most of the heat is generated by switching losses in the power semiconductors. It is dissipated via heat sinks or by forced cooling with fans. If heat transfer is restricted or impeded, for instance by fan failure or excessive ambient temperature, this can quickly lead to damage or destruction of the converter – and in extreme cases fire can even break out.

A PTC thermistor makes it possible to intervene in operation of the power stage directly and with a measured response in the event of excess temperature. PTC thermistors belong to the family of nonlinear resistors.

A PTC thermistor makes it possible to intervene in operation of the power stage directly and with a measured response in the event of excess temperature. PTC thermistors belong to the family of nonlinear resistors.

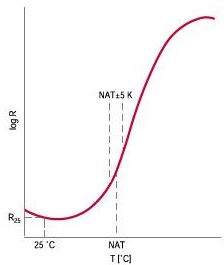

At room temperature, the PTC Thermistor has a relatively low resistance. As the temperature rises, this initially drops slightly and then rises steeply. This steep section of the R/T characteristic is used for temperature measurement.

R/T Curve of a PTC Thermistor

For Sensor applications, a nominal threshold temperature is defined in the steep section of the R/T curve; the characteristic is very narrowly specified near this section.

Simple but effective for direct monitoring of power supply temperature

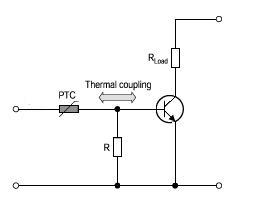

This temperature characteristic can be used in a very simple circuit for direct monitoring of power supply temperature. For this purpose, the PTC Thermistor is inserted in the control circuit of the power stage.

In the example shown here, it is located in the base of the switching transistor. Good thermal coupling between thermistor and transistor is essential. If the temperature rises above a specific value, the thermistor’s resistance increases very quickly and thus cuts off the base current to the transistor, which no longer switches. As soon as the module has cooled down sufficiently, the thermistor returns to its original low-resistance state.

Thanks to this direct intervention by the PTC sensor in the control stage of the power semiconductor, elaborate control circuitry can be dispensed with, saving costs, time and space. This PTC Thermistor circuit is completely maintenance-free, extremely reliable and subject to no cyclic limitations.

PTC Thermistors Monitoring Temperature in DC/DC Converter

PTC Thermistor monitoring temperature in DC converter

At excessive temperature, the resistance of PTC thermistor increases, cutting of the base current to the transistor.

All-rounders in temperature monitoring

PTC thermistor limit temperature sensor is available with nominal threshold temperatures from 60C to 130C, so the optimum can be selected for the application. Consideration must be given to the temperature stability of the semiconductor, the surrounding components, the circuit board material, and the desired operating life of the module.

To ensure fast and reliable turnoff of the power output stage, a PTC thermistor is selected whose resistance is high before the module reaches its maximum operating temperature.

PTC thermistors are designed for optimum protection of electrical and electronic modules and equipment against excess temperature. More applications for limit temperature sensors based on PTC thermistors. Examples include air conditioning, heating control, small and domestic appliances, plus temperature protection of industrial motors.