Linear Silicon PTC Thermistors Temperature Sensors

Unit: mm

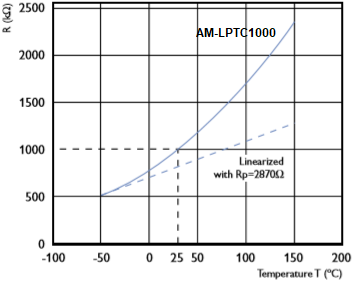

AMWEI AM-LPTC1000 RT Curve, linearized with parallel resistor

Silicon PTC Thermistors Temperature Sensors is PTC thermistors made of monocrystalline silicon material, used in drives and motors, equipment, industrial automation control for temperature sensing measurement and control function, by utilizing silicon PTC thermal property that resistance increases with the temperature rises in linearity.

Silicon PTC Thermistors Temperature Sensors resistance increases with the temperature rises in linearity, displays a virtually linear positive temperature coefficient over their entire temperature range, ensuring highly accurate measurements.

A linearization resistor can be easily added where further linearization is required. .

The construction material is mainly semiconductor monocrystalline silicon, sometimes referred to as silistors.

As the temperature coefficient is positive, the silicon temperature sensors exhibit fail-safe operation when a system overheats.

Furthermore silicon is inherently stable, so silicon temperature sensor is extremely reliable, has very long operational lifetimes.

Hermetically sealed glass DO35 package, axial leaded, Dumet wire, 2 leads.

Silicon PTC thermistors temperature sensor in small dimension, tightness, available for tape package, convenient for automatic installation.

- Silicon temperature sensors have a TK (temperature coefficient) which is nearly constant over the complete temperature range. Temperature coefficient:α25/50≥0.7%/C.

- Excellent long term stability, annual diversification rate≤0.01C/per year, temperature drifts during the lifetime of silicon temperature sensor are negligible.

- Temperature measurement range: -55C to +150C. AM-LPTC600 can upto +180C.

- AMWEI silicon PTC thermistors temperature sensors can withstand more than +200C without damage.

- Thermal Time Constant: 21 seconds max in still air.

- Dissipation factor:1.5mW/C.min.

- Insulation resistance: 100 Million ohm min. (DC=100V)

- Maximum operating current:8mA. Rated operating current: 2mA.

- Rated power:50mW max.

- Typical resistance @25C 600Ω 1000Ω 1600Ω 2000Ω. Other R25 resistance, such as 200Ω 1200Ω 1870Ω, 4050Ω, 4700Ω can be made upon request.

- Can also make specific customer tailored housing cable Silicon PTC thermistor Temperature Probe Assembly upon request. Copper Tube Housing for reference.

For AMWEI AM-LPTC600, rated resistance @100C 1000 ohm, tolerance 3%, 5%,

substitute to Philips NXP Silicon Temperature Sensors KTY84/130, KTY84/150, KTY84/151.

Widely applied in the temperature sensing and controls in drives and motors, spindles, inverters and control systems, etc.

For AMWEI AM-LPTC1000, rated resistance @25C 1000 ohm, tolerance 1%, 2%, 3%, 5%,

alternative to Philips NXP Silicon Temperature Sensors KTY81-1, KTY83-1 series,

type no.KTY81-110, KTY81-120, KTY81-121, KTY81-122,KTY81-150, KTY81-151, KTY81-152, KTY83-110, KTY83-120, KTY83-121, KTY83-122, KTY83-150, KTY83-151, KTY83-152.

This part silicon temperature sensor is widely used in wiring harnesses built in transmission units, vehicles, etc.

For AMWEI AM-LPTC2000, rated resistance @25C 2000 ohm, tolerance 1%, 2%, 3%, 5%,

Philips NXP Silicon Temperature Sensors KTY81-2 KTY83-2 series cross,

type no. KTY81-210, KTY81-220, KTY81-221, KTY81-222,KTY81-250, KTY81-251, KTY81-252.

Widely applied in the temperature sensing and control of instrument, equipment, compressor, process control, etc.

| Temperature | AM-LPTC200 | AM-LPTC600 | AM-LPTC1000 | AM-LPTC1000 175C |

AM-LPTC1600 | AM-LPTC2000 | AM-LPTC4000 | |

|---|---|---|---|---|---|---|---|---|

| C | F | |||||||

| -55C | -67F | \ | \ | 490 ohm | 487 ohm | \ | 980 ohm | \ |

| -50C | -58F | \ | \ | 515 ohm | 512 ohm | \ | 1030 ohm | \ |

| -40C | -40F | \ | 359 ohm | 567 ohm | 562 ohm | \ | 1135 ohm | \ |

| -30C | -22F | 130 ohm | 391 ohm | 624 ohm | 617 ohm | 998 ohm | 1247 ohm | 2485 ohm |

| -20C | -4F | 141 ohm | 424 ohm | 684 ohm | 678 ohm | 1091 ohm | 1367 ohm | 2739 ohm |

| -10C | 14F | 153 ohm | 460 ohm | 747 ohm | 743 ohm | 1192 ohm | 1495 ohm | 3001 ohm |

| 0C | 32F | 165 ohm | 498 ohm | 815 ohm | 811 ohm | 1300 ohm | 1630 ohm | 3279 ohm |

| 10C | 50F | 179 ohm | 538 ohm | 886 ohm | 884 ohm | 1415 ohm | 1772 ohm | 3576 ohm |

| 20C | 68F | 192 ohm | 581 ohm | 961 ohm | 951 ohm | 1537 ohm | 1922 ohm | 3888 ohm |

| 25C | 77F | 200 ohm | 603 ohm | 1000 ohm | 1000 ohm | 1600 ohm | 2000 ohm | 4050 ohm |

| 30C | 86F | 209 ohm | 626 ohm | 1040 ohm | 1040 ohm | 1665 ohm | 2080 ohm | 4218 ohm |

| 40C | 104F | 224 ohm | 672 ohm | 1122 ohm | 1125 ohm | 1798 ohm | 2245 ohm | 4565 ohm |

| 50C | 122F | 242 ohm | 722 ohm | 1209 ohm | 1213 ohm | 1938 ohm | 2417 ohm | 4925 ohm |

| 60C | 140F | 258 ohm | 773 ohm | 1299 ohm | 1304 ohm | 2077 ohm | 2597 ohm | 5300 ohm |

| 70C | 158F | 275 ohm | 825 ohm | 1392 ohm | 1400 ohm | 2230 ohm | 2785 ohm | 5690 ohm |

| 80C | 176F | 294 ohm | 882 ohm | 1490 ohm | 1500 ohm | 2393 ohm | 2980 ohm | 6095 ohm |

| 90C | 194F | 313 ohm | 940 ohm | 1591 ohm | 1605 ohm | 2562 ohm | 3182 ohm | 6518 ohm |

| 100C | 212F | 333 ohm | 1000 ohm | 1696 ohm | 1713 ohm | 2728 ohm | 3392 ohm | 6958 ohm |

| 110C | 230F | 360 ohm | 1062 ohm | 1805 ohm | 1821 ohm | 2880 ohm | 3607 ohm | 7415 ohm |

| 120C | 248F | 383 ohm | 1127 ohm | 1915 ohm | 1933 ohm | 3006 ohm | 3817 ohm | 7830 ohm |

| 125C | 257F | \ | \ | \ | \ | \ | \ | 8002 ohm |

| 130C | 266F | 403 ohm | 1194 ohm | 2023 ohm | 2047 ohm | 3092 ohm | 4008 ohm | \ |

| 140C | 284F | 423 ohm | 1262 ohm | 2124 ohm | 2168 ohm | \ | 4166 ohm | \ |

| 150C | 302F | 436 ohm | 1334 ohm | 2211 ohm | 2282 ohm | \ | 4280 ohm | \ |

| 160C | 320F | \ | 1407 ohm | \ | 2384 ohm | \ | \ | \ |

| 170C | 338F | \ | 1482 ohm | \ | 2448 ohm | \ | \ | \ |

| 175C | 347F | \ | \ | \ | 2512 ohm | \ | \ | \ |

| 180C | 356F | \ | 1560 ohm | \ | \ | \ | \ | \ |

- Motion control temperature sensor, temperature sensing and controls in drives and motors, spindles, inverters and control systems, etc.

- Industrial automation control equipment.

- Home appliance temperature detection and compensation.

- Precision circuit and crystal oscillator temperature compensation.

- Temperature compensation of silicon semiconducting devices.

- Temperature compensation of instrumentation amplifier.

- A/D converter temperature compensation.

- Micro motor timing control.

- Automobile temperature detection and control.

- Medical equipment temperature detection and control.

- Linear PTC thermistors applications also include transmission, engine oil and coolant, heating system, overheating protection, amplifiers, power supplies, transducers, telemetry, computers, magnetic amplifiers, thermometry, meteorology, temperature regulation and over-temperature protection.

Temperature measuring circuit diagram using a AM-LPTC1000 silicon sensor

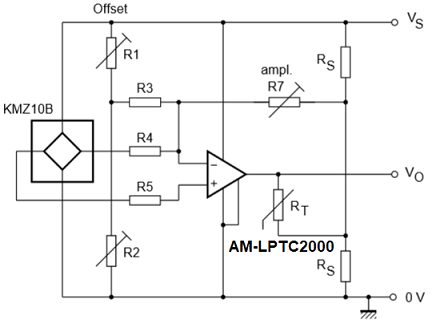

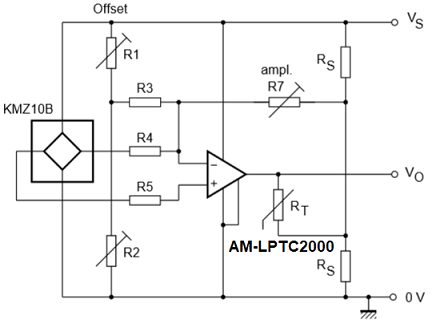

AM-LPTC2000 Temperature Compensation Circuit Diagram

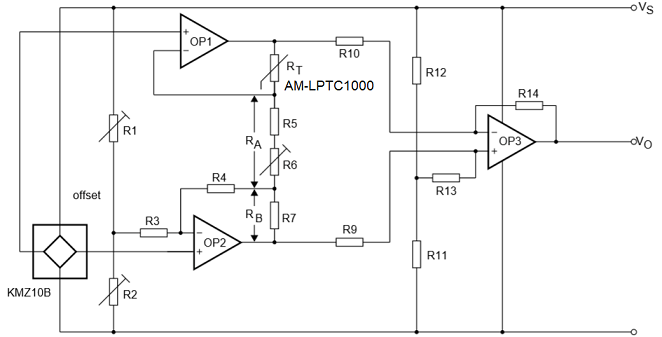

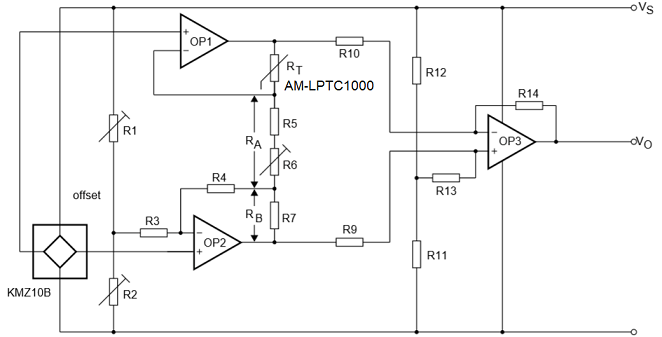

Evaluation circuit diagram with AM-LPTC1000 instrumentation amplifier

Temperature measuring circuit diagram using a AM-LPTC1000 silicon sensor

AM-LPTC2000 Temperature compensation circuit diagram

Evaluation circuit diagram with AM-LPTC1000 instrumentation amplifier

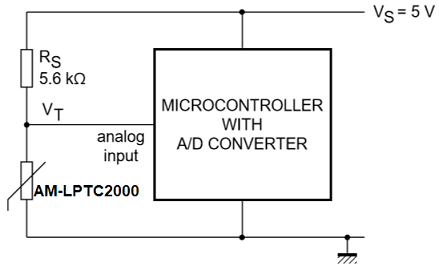

AM-LPTC2000 Temperature compensation for converters

When an A/D converter is integrated with a microcontroller, temperature compensation is required.

Using a AM-LPTC2000 temperature sensor in series with linearization resistor RS. This voltage divider provides a linear temperature dependent voltage VT of between 1.127 V and 1.886 V over the range 0 to 100 °C. This voltage is used as a reference for the A/D converter. The linear slope ‘S’ of VT = 7.59 mV/ K.

Minimum lead wire length tailored to shall be ≥8mm.

In lead wire bending, bending point shall be more than 2mm away from glass body part.

Mounting and Handling Recommendations

Excessive forces applied to a sensor may cause serious damage. To avoid this, the following recommendations should be adhered to:

- No perpendicular forces must be applied to the body

- During bending, the leads must be supported

- Bending close to the body must be done very carefully

- Axial forces to the body can influence the accuracy of the sensor and should be avoided

- These sensors can be mounted on a minimum pitch of >5 mm

Soldering and Welding

- Avoid any force on the body or leads during, or just after, soldering.

- Do not correct the position of an already soldered sensor by pushing, pulling or twisting the body.

- Prevent fast cooling after soldering.

- For hand soldering, where mounting is not on a printed-circuit board, the soldering temperature should be <300C the soldering time <3 s and the distance between body and soldering point >1.5 mm.

- For hand soldering, dip, wave or other bath soldering, mounted on a printed-circuit board, the

- soldering temperature should be <300C, the soldering time <5 s and the distance between body and soldering point >1.5 mm.

- The distance between the body and the welding point should be >0.5 mm. Care should be taken to ensure that welding current never passes through the sensor.

Other AMWEI PTC NTC Thermistors for Temperature Sensing

Content Headline

Thermistors Application

FAQ Silicon PTC Sensor

It is NOT exactly the same.

AMWEI silicon PTC Thermistors temperature sensor AM-LPTC600 is DO35 package, glass encapsulated part 4.6mm max.

Max. Temperature measurement can only upto 180C.

More information on AMWEI silicon PTC Thermistors temperature sensor AM-LPTC600 can be found on AMWEI Linear Silicon PTC Thermistors Temperature Sensors Product Page.

It is NOT exactly the same.

AMWEI silicon PTC Thermistors temperature sensor AM-LPTC1000 is in axial leaded glass encapsulated DO35 package.

The Resistance vs. Temperature Data is NOT exactly same.

AMWEI Silicon PTC Thermistor Sensor is NOT Cathode Marked.

Standard package is loose bulk package.

Taped package can be made upon request.